The author is the director of nutrition research and innovation with Rock River Lab Inc, and adjunct assistant professor, University of Wisconsin-Madison’s Dairy Science Department.

Historic averages have been in the 50s and low 60s. The historic “normal” range of 50 to 70 can now better be described by scores of 60 to 70. The goal for today should be considered 75 or greater, as some have achieved scores of 85. These benchmarks apply to fermented corn silage, though, and a separate set of benchmarks exist for unfermented, whole-plant chopped corn (not yet silage).

Improved processing

Marked improvement in kernel processing, to the benefit of dairy and feedlot performance, is coming by way of advances in machinery design, maintenance, and management. Speaking from a machinery standpoint, self-propelled forage harvester power and capabilities have improved, and kernel processor design has markedly advanced (for example, contemporary processors with shredding characteristics related to improved KPS). These engineering advances have contributed to the 5 to 10 unit gain in U.S. average KPS over the past decade.

Those owning, operating, and servicing the forage harvesters have also better recognized the kernel processor’s capabilities and maintenance needs. Many measure KPS during feedout as a year over year evaluation of chopper performance.

With research efforts underway to better understand the relationship between KPS and rumen starch digestion, I hypothesize that a 5 to 10 unit gain in KPS may improve corn silage starch digestion by an equivalent amount. A 5 to 10 unit gain in corn silage rumen starch digestion can easily equate to an additional pound of milk per cow eating a high corn silage diet. Work with your dairy advisory team to consider how these factors could play into your margins.

Recognizing the substantial impact on feedlot gains and dairy performance, those aggressively managing during harvest are routinely monitoring KPS. Some have gone as far as to purchase the laboratory equipment needed to run the assay. The farms and chopping crews are using these measures real-time to adjust roll gaps and other chopper and kernel processor settings day to day.

Silage KPS changes

With likely thousands of freshly chopped corn kernel processing scores now completed, the industry is currently recognizing that freshly chopped corn KPS goals are different from fermented silage.

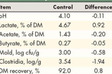

In a January 2016 Hay & Forage Grower article, Luiz Ferraretto from the University of Florida discussed his team’s research showing how KPS changes over time and described the mechanisms. I recommend referring to this article for further explanation. In short, KPS improves through fermentation via the same mechanisms that starch digestibility improves with ensiling – the starch chunks in the kernel break down and fall apart into smaller pieces over time.

A lower fresh KPS

This information is percolating through our industry but is not yet common knowledge. In a recent southern U.S. chopper support discussion with Randy Shaver from the University of Wisconsin, Ferrareto, and forage consultant Chris Wacek-Driver, we theorized how a 75 to 80 KPS goal for fermented silages is not realistic for freshly chopped corn. We recognized that corn silage likely gains up to 10 units or more during ensiling, and then mutually agreed that if the KPS goal is 75 at feedout, then a realistic benchmark should be in the 60s during chopping.

The story gets deeper given recent field observations by Chr. Hansen’s forage specialist team. Keith Bryan noted that the KPS gain during ensiling may also depend on moisture. Initial observations suggest that wetter, whole-plant chopped corn (68 to 70 percent moisture) KPS does not respond to ensiling to the same extent that drier corn does. Thus, the freshly chopped corn KPS goal will also depend on moisture.

Mechanical factors involved

Bryan and Ferraretto have both also commented that mechanical processing (bagging or rotary defacing for feedout) can further improve fresh chopped corn KPS. More research and understanding are warranted here, but keep these observations and interactions in mind when setting goals this corn chopping season.

Reflecting on the points discussed here, work with your nutritionist and chopping crew to set realistic goals. Nutritionists like to see complete kernel destruction (no visible kernels), yet at times this is tough to achieve. Diesel fuel and machinery costs might make it economically impractical. Understand that freshly chopped whole-plant corn KPS will more than likely never be 75 or greater. Know that when corn kernel maturity and dry matter advance, maximum kernel breakage becomes more and more critical.

Consider that plant moisture and possibly kernel maturity may interact with ensiling to dictate resulting KPS during feedout. While further research is necessary to develop rock solid benchmarks, a freshly chopped corn likely needs to be averaging 65 KPS or better to achieve ensiled corn silage KPS levels in the 75 to 80 range.

This article appeared in the August/September 2018 issue of Hay & Forage Grower on page 27.

Not a subscriber? Click to get the print magazine