Water does not contribute to your forage economic value when balancing diets or pricing forage. Instead, the water is dried off, and it’s the grams (g) of nutrients and minerals per 100 g of total feed that drive the economic and nutritional value for your feed per ton.

Think of this like the fuel gauge on your truck. The remaining fuel volume is measured with a float sensor and related back to the total tank volume (for example, 1/4 or 1/2 tank).

To get down to business or balance diets, the water must be accounted for but only so that dry matter (DM) is determined. In most cases, moisture is determined indirectly as weight lost after drying. In this practice, the sample is dried and the sample weight left after drying is compared to the original starting weight.

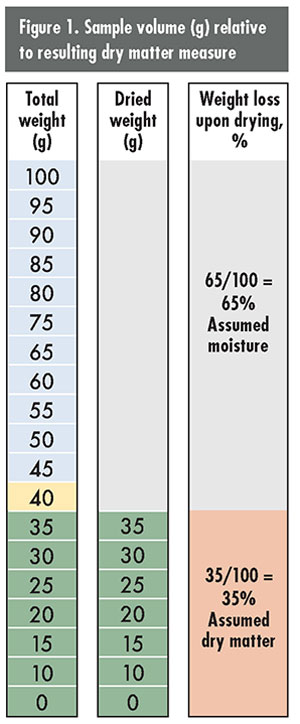

The process is visually depicted in Figure 1 and the math looks like this:

- Weigh out 100 g wet forage

- Dry the forage to a stable weight

- Weigh the residual forage (in this case, 35 g)

- Assumed DM (weight left after drying) = 35 g divided by 100 g = 35 percent

Theoretically, the process highlighted above is simple. Yet, the compounds that dry off silage and haylage samples are more than just water, and not all ovens or drying techniques are created equal. Ensiling feeds creates fermentation acids, alcohols, and volatile nitrogen compounds from carbohydrates and protein.

The sweet, alcohol, or stinky smells with silages are all volatile compounds. These compounds have nutritional value but are volatilized to various extents when samples are dried.

Accuracy is a must

There are numerous research papers, dating as far back as 80 years, describing errors associated with forced-air oven drying and how to account for these. Yet, in the past 15 to 30 years, this knowledge has been lost and isn’t taken into account when valuing forages or balancing diets.

The range in nonwater volatile compound losses (or DM error) associated with different oven drying techniques can be as little as zero with fresh feed or as great as 10 units or more with extensively fermented feeds that contain considerable fermentation compound levels. The range also differs with drying techniques. This may be scary to recognize as there are millions of tons of forage, and hundreds of millions of dollars exchanged for forages valued on a dry matter basis. Yet all is not lost.

In practice, your farm can deal with accuracy questions by turning your attention to recognizing the issues in play and then agreeing upon a repeatable DM approach. Use a consistent approach and determine DM as close to harvest as possible. Do not wait until the harvest has started and the choppers are rolling or wait until the feed has fermented and fermentation compounds contribute to DM errors.

If buying fermented forage, agree upon a DM protocol prior to negotiating price. Work with your nutrition and agronomic consultants, forage growers, or brokers and host a strategic business meeting ahead of the growing season or negotiations. Develop an agreement for a consistent DM determination approach.

Focus your attention on an approach that provides both the most accurate and repeatable results to value your forages or balance diets. This may be an on-farm approach or working with a reputable feed analysis laboratory.

This article appeared in the November 2019 issue of Grower on page 10.

Not a subscriber? Click to get the print magazine.