Poor kernel processing impacts the bottom line |

| By Luiz Ferraretto |

|

|

|

The author is an assistant professor of livestock nutrition in the department of animal sciences, University of Florida.  Starch, located in the endosperm of corn kernels, accounts for more than half of the energy provided by corn silage. However, corn is a seed and has a hard coat (pericarp) that surrounds and protects the embryo and the starch endosperm from external threats. Consequently, the breakdown of the pericarp and the resulting exposure of starch endosperm must be the primary objective at harvest to maximize available energy. This explains why kernel processing is one of the most important factors affecting starch digestibility in corn silage. The economic consequences of poorly processed corn silage are substantial. Several components come into play. It’s not just roll setting It is well established that the use of kernel processors enhances kernel breakdown at harvest. However, roll-gap settings are a key player to obtain greater starch digestibility and corresponding milk production by dairy cows. A review from the University of Wisconsin reported that the benefits of using a kernel processor is achieved only when rolls are set with gap settings between 1 to 3 millimeters (mm), or 0.04 to 0.12 inch. However, other harvesting practices may impair the efficacy of kernel processors even when rolls are properly set following these guidelines. Chop length is one of these factors. The same review article from the University of Wisconsin reported that kernel processing was effective when theoretical length of cut (TLOC) settings on choppers were 0.37 to 1.13 inches but not when they were set longer. Possibly, at a longer TLOC, the coarse stover portion of corn silage may inhibit kernel breakage during passage through the rollers, thereby reducing the effect of processing. When that review was conducted, however, data evaluating shredlage processors were not available. This new processor type may attenuate this negative effect by causing greater damage to the kernels at a longer TLOC. Two experiments from the University of Wisconsin evaluated the shredlage processor (1.18 or 1.02 inches of TLOC settings) in comparison with a conventional processor (0.75 inch of TLOC setting). In both experiments, shredlage had greater kernel processing, starch digestibility, and lactation performance than conventionally processed silage. Furthermore, efficacy of kernel processing is reduced as maturity progresses. This information is important as harvesting of mature corn plants to achieve greater yields of starch became a common practice. However, starch is not accumulating by itself in the kernel with maturation. As maturity progresses, an elevated proportion of vitreous endosperm accumulates in the kernel, thereby boosting kernel hardness, which in turn may cause kernels in very dry, mature corn silage to be less susceptible to breakage. This explains why kernel processing was effective for corn silage containing 32 to 40 percent dry matter (DM) but not when corn silage was above 40 percent DM in the Wisconsin review. In addition, there is no evidence that shredlage processors are more effective than conventional processors in corn silage harvested above 40 percent DM. Therefore, optimum kernel breakdown requires continuous monitoring of plant maturity within and across fields, proper roll gap and TLOC settings, regular processor maintenance, and continuous monitoring of kernel breakage during harvest. Poor processing costs

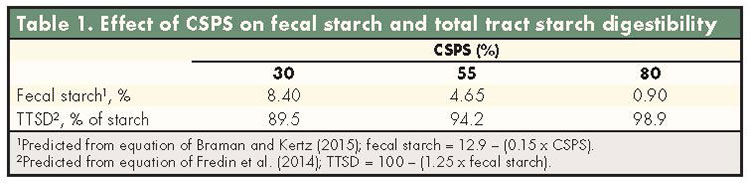

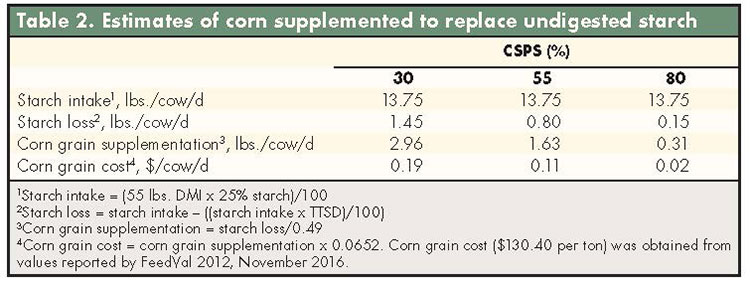

Although the benefits of greater kernel processing on milk production is well known, it is very difficult to reliably estimate its economic impact. The exercise presented and discussed in this article is an attempt to provide some numbers to dairy producers and their nutritionists as a starting point. In order to do that, however, a hypothetical scenario had to be created and three values of corn silage processing score (CSPS; percent of starch passing through a 4.75 mm sieve) were arbitrarily chosen. Table 1 lists the CSPS values chosen and predicted fecal starch and total tract starch digestibility (TTSD) values.  The second step (Table 2) was to estimate for each CSPS the amount of corn that would need to be supplemented in order to obtain the same amount of digestible starch as if TTSD was 100 percent. The following assumptions were made: Dietary starch was 25 percent of DM and consumption of DM was 55 pounds per day. Consequently, it was assumed that cows were eating 13.75 pounds of starch per day. Based on TTSD, values of starch loss in the manure were calculated and ranged from approximately 0.15 to 1.5 pounds. If we assume that corn grain has 70 percent starch and 70 percent ruminal in vitro starch digestibility, for each pound of corn supplemented only 0.49 pound of digestible starch is provided. Thus, dividing starch loss by 0.49 we can determine the amount of corn necessary to compensate for undigested starch. Although the numbers used in this exercise may not be representative of every dairy, it is a good indication of potential economic loss related to poor kernel processing. Thus, it is recommended that dairy farmers and their nutritionists perform similar calculations based on their own scenarios and goals. This article appeared in the January 2017 issue of Hay & Forage Grower on pages 26 and 27.

Not a subscriber? Click to get the print magazine. |