This item has been supplied by a forage marketer and has not been edited, verified or endorsed by Hay & Forage Grower.

It’s nearly time to start thinking about corn silage harvest. Corn silage is typically an economical source of energy in dairy cattle diets, and quality silage begins with quality forage. Ensiling can only preserve what is already present in the crop. This is especially important because starch, while not a required nutrient for cattle, is an economical source of net energy for the cow and a source of fermentable energy for rumen microbes, providing metabolizable protein. Both energy and starch are required nutrients for cows. Therefore, timely planning must be done before beginning the harvest of corn silage.

Optimal dry matter

One of the most important factors to consider when harvesting corn silage is dry matter. As the plant matures and harvest approaches, begin walking the fields and tracking conditions so that timely harvest plans can be made. Every year and each acre are different and present diverse conditions.

Harvesting before corn reaches optimal moisture will result in:

- decreased yield per acre

- decreased starch deposition

- poor silage fermentation

- On the other hand, delaying harvest will result in:

- reduced fiber digestibility

- reduced starch digestibility

- poor packing density, increasing the incidence of mold and spoilage

When monitoring fields, a quick moisture estimate can be done by breaking a cob in half and looking at the kernels within. The milk line — an apt name for the white color line on the kernel — will move from the outer edge of the kernel toward the cob. Harvest should typically begin when the milk line reaches the halfway mark — i.e., when half of the kernel is milky and the other half is doughy, as shown in Figure 1. It is important to note that the milk line should only provide a rough estimate point and should not be relied upon solely to determine moisture content. Many other factors, including field location, planting date, hybrid and weather, can affect the milk line and its relationship to whole plant dry matter. Whole plant moisture will typically change by 0.5 units per day and can change up to 1.0 units in dry conditions, so plants must be monitored closely as they begin to reach optimal dry matter.

Factors affecting corn plant moisture and dry down rate in the field are:

- • geographic location

- • stage of maturity

- • hybrid

- • crop management

- • soil type

In order to reach maximum fermentation and compaction, there are variations in desired dry matter concentration among storage structure.

Recommended dry matter:

• Bunkers and drive-over piles: 32-38 percent dry matter

• Silage bag: 35-38 percent dry matter

• Upright silo: 35-40 percent dry matter

Measure the moisture content — don’t just estimate it.

How to determine moisture on-farm

A commercial forage moisture tester, food dehydrator or microwave oven can be used to quickly determine moisture content. To determine whole plant moisture, gather 10-15 representative stalks from the field. The plants must also be chopped.

If using a microwave oven to determine moisture content:

- Weigh out 100 grams of fresh forage on a plate or container. (Be sure to subtract the weight of the container.)

- Spread the fresh forage out evenly and place in the microwave.

- Heat on high for four minutes.

- Remove the silage and container from the microwave and record the weight.

- Heat the sample in the microwave for one minute.

- Remove the sample and record the weight.

- Repeat steps 5 and 6 until the weight stabilizes.

- Once the weight stabilizes, record the weight and subtract the remaining weight from 100. For example, if the weight stabilized at 35 grams, the dry matter would be 35 percent and the moisture would be 65 percent (100-35=65).

To get an accurate estimate, be sure that the same trained individual determines the dry matter. Work with your Hubbard Feeds representative to ensure proper dry matter testing and timely harvest planning.

Maturity

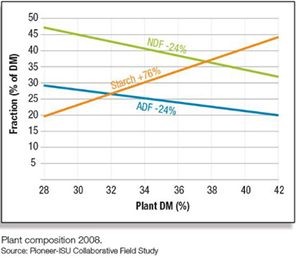

As plants mature, starch increases. This happens as the result of several changes within the kernel, including reduced moisture concentration, increased vitreousness and the encapsulation of starch granules by a protein matrix. However, be aware that — if harvest is delayed — to achieve greater starch levels, kernel processing is crucial to ensure adequate digestibility. Fiber digestibility also begins to drop as the plant matures, but this drop occurs at a slower rate than the increase in starch (Figure 2). Therefore, kernel processing becomes crucial as the plant matures, as do hybrids that have hard or dense starch forms, in order to increase ruminal and total tract starch digestibility. Dry matter is a key indicator of kernel processing, with research showing an increase in total tract starch digestibility when corn silage is between 32 and 40 percent dry matter, as compared to unprocessed corn silage. During processing, corn kernels should be broken into four pieces or more in order to maximize digestibility.

How to evaluate kernel processing on farm:

Fill a five-gallon pail roughly halfway with water and place two to three handfuls of processed corn silage in the water.

Gently agitate the silage to help separate the kernels from the stover mat.

Skim the floating stover from the water.

Carefully drain the water from the pail and remove the kernels for evaluation.

To be considered properly processed, there should be almost no whole or cracked kernels. The presence of several whole kernels indicates that processing is insufficient. If there are cracked or broken kernels, there may be opportunities to improve the processing. Since the evaluation of kernel processing using this technique is subjective, contact your Hubbard Feeds representative for assistance.

Timing is everything with corn silage harvest. Be aware of the conditions within the field as we move into corn silage season so timely harvest planning decisions can be made, resulting in high quality silage.

References

https://fyi.uwex.edu/forage/on-farm-moisture-testing-of-corn-silage/

http://corn.agronomy.wisc.edu/Silage/S004.aspx

http://ipcm.wisc.edu/blog/2016/08/timing-corn-silage-harvest/

https://fyi.uwex.edu/forage/making-sure-your-kernel-processor-is-doing-its-job/

Brouk, M. 2018. Harvest and Storage Management. Presented at the Hubbard Dairy Forage Focus Meeting. May 1 and 2, 2018. Bloomington, MN