Summer weather can ruin our favorite foods – take a melted ice cream cone for instance. Hot, humid air can also ravage the quality of livestock feed, but these consequences can be much more serious.

Starchy forages, such as silage, are susceptible to being aerobically unstable. Wet by-products and other high-moisture ingredients carry the same risk, meaning these feed components can spoil quickly when exposed to oxygen in combination with high temperatures and humidity.

Liz Binversie and Matthew Lippert, extension agricultural educators with the University of Wisconsin-Madison, explain that aerobic instability causes yeast growth and nutrient loss in feed. This can be detrimental to cattle because their intakes may already be compromised due to heat stress.

“Yeasts use nutrients and lactic acid as sources of energy,” the authors share. “The growth of yeasts sets off a chain reaction that starts with heating and leads to the loss of volatile acids, a rise in pH, the growth of undesired molds, and ultimately, instability.”

Pack it

Maintaining aerobic stability of silage begins with proper packing and sealing after harvest. Poorly packed silage will retain more oxygen and be more unstable at feedout. Conversely, densely packed forage improves fermentation and lowers the rate of oxygen penetration.

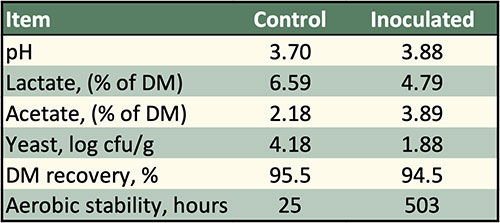

Farmers can take storage a step further by inoculating silage. The authors note that Lactobacillus buchneri is a heterofermentative bacteria and is commonly used to convert lactate into acetate and 1,2-propanediol. This can improve silage’s pH while suppressing yeast and mold growth. See table below.

Although this tactic can be helpful, many of the problems it solves are the result of earlier poor management. Focus on improving storage and feedout practices before relying on inoculation.

Feed it out

To remove feed, use a facer instead of a bucket. This tool leaves a smoother face devoid of air pockets and overhangs where oxygen can infiltrate. Also make sure to regularly check silage bags and bunker plastic for tears and holes that can also permit unwanted air.

Even after taking the previous measures, air can penetrate stored feed in a well-packed bunker up to 35 inches per day. The authors recommend an optimal removal rate of 12 inches per feeding to use up what has already been exposed to air and get ahead of further heating and spoiling.

Take out enough feed to hinder oxygen’s adverse effects on the pile, but don’t remove too much that it will sit out for a long time. Binversie and Lippert suggest only removing enough feed for each feeding.

“Carefully remove silage to avoid excess that will not be fed that day and will spoil,” the extension educators assert. “If feeding multiple times per day, remove silage multiple times per day. Leaving feed out will cause greater feed loss, costing you money.”

Feeding multiple times per day, as well as at cooler times of the day, are also good practices. Cows in heat stress can have lower feed intakes, so delivering feed in smaller batches during temperatures they are most comfortable in may encourage greater consumption.

After feeding cattle, monitor total mixed ration (TMR) temperatures in the feedbunk and identify any heating. Also look for molds and test for mycotoxins, then manage accordingly. Feed ingredients with high yeast counts, such as wet distillers grains, could be the cause and should be excluded from the ration.

Adding acid buffers and other preservatives is another option to protect TMRs from spoiling. These products can prevent yeast proliferation and enhance TMR aerobic stability.

Amber Friedrichsen is serving as the 2021 Hay & Forage Grower editorial intern. She currently attends Iowa State University where she is majoring in agriculture and life sciences education-communications with a minor in agronomy. Friedrichsen grew up on her family’s diversified crop and livestock farm near Clinton, Iowa.